EN

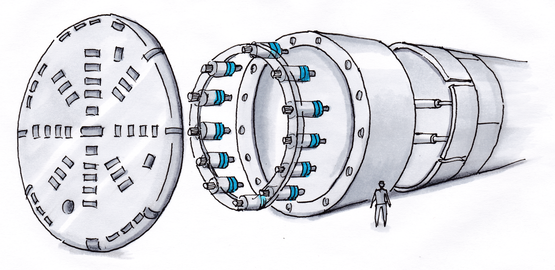

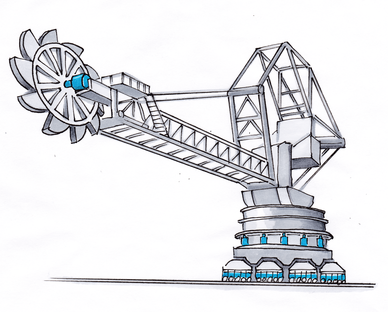

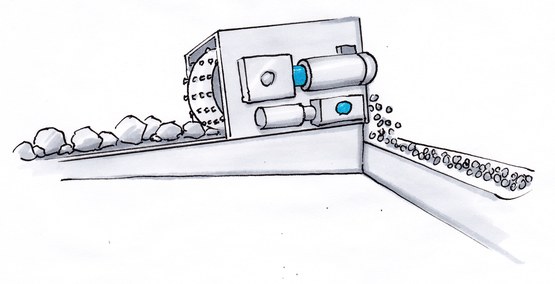

Tunnelling and underground mining

Reliable protection for heavy duty applications

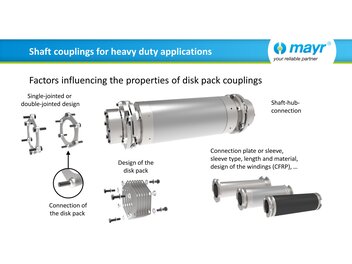

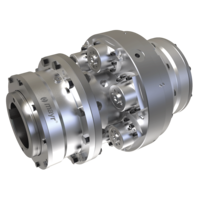

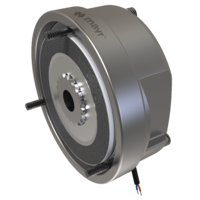

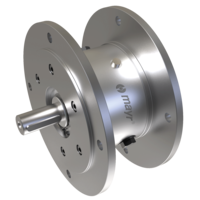

In the field of heavy load applications, such as in tunnelling or mining machines, mayr® power transmission stands for future-orientated solutions with high performance density as well as high torques and speeds. Wherever machines eat their way through rock, burst open stone and hold and decelerate high loads, only robust, resistant and sturdily-dimensioned clutches and brakes can cope with the extreme conditions. In the drive line, they guarantee a secure connection between the shafts, ensure permanently reliable overload protection and can, in case of emergency, absorb peak loads with extremely high friction work: The clutches and brakes by mayr® power transmission ensure maximum operational safety and productivity in the large systems.

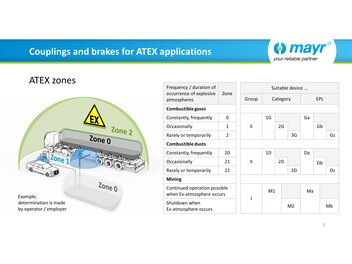

Recommendation