New possibilities for monitoring spring applied brakes in servo motors

The ROBA®-brake-checker module by mayr® power transmission is not only able to monitor and supply safety brakes without the use of sensors. In an advanced version, it also supplies data, and therefore provides intelligent safety. Now the company has also approved small brake sizes for monitoring with the module. This opens up new possibilities for brake monitoring – in particular also for safety brakes in servomotors and for applications in the fields of robotics and automation.

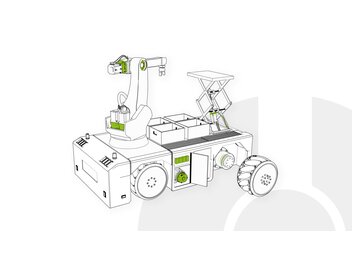

Whether in industrial robots collaborating with humans in production lines or in medical engineering- robot arms must not drop or crash in an uncontrolled manner after power switch-off or in case of power failure or emergency stop. This is guaranteed by safety brakes which hold the robot joints in position safely and reliably. mayr® power transmission, the specialist for safety brakes, torque limiters and shaft couplings from Mauerstetten in the Allgaeu region provides high-performance safety brakes for installation into servomotors with their ROBA®-servostop® series. A special hollow shaft design in slim constructional design and of a low weight has been especially tailored to the requirements in robotic applications and easily withstands the demanding operating conditions. The intelligent ROBA®-brake-checker module now opens up new possibilities for the monitoring of these brakes. With a new module design and thanks to even more accurate evaluation, it is now possible to also supply and monitor small brake sizes. Previously it was not even possible to monitor these brakes due to the small air gaps .

Safety becomes visible

The ROBA®-brake-checker module works without sensors. It detects the movement of the armature disk through extended analysis of current and voltage, and knows what condition the brake is in. In addition to the switching condition, temperature and wear, the ROBA®-brake-checker also monitors the pull-in distance or tensile force reserve, i.e. whether the magnet is still able to attract the armature disk. With the new module, substantially more parameter are thus depicted than with microswitches and sensors. On reaching the tensile force reserve, the ROBA®-brake-checker emits a warning signal early enough so that a certain operating time for the brake is still possible.

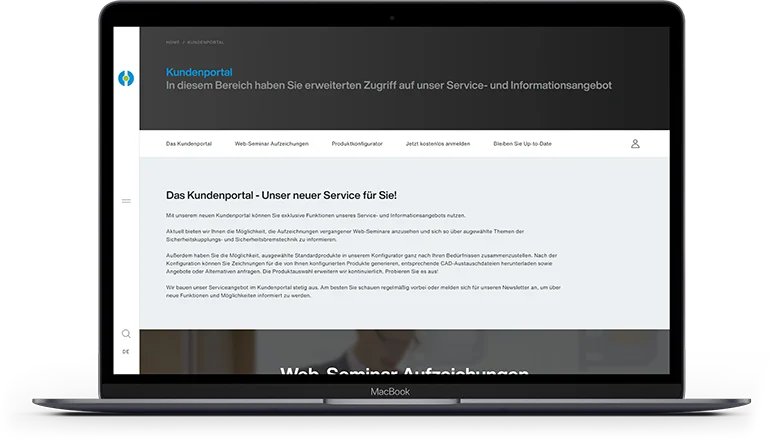

In addition to the signal itself, the module can also supply – in an advanced version – for example through an optical interface, data on the switching time, the current, the voltage, the resistance, the power and the relative attraction current. The latter permits conclusions to be drawn regarding critical brake operating conditions. Using an evaluation programme, the customer can see whether everything is running smoothly or whether there is work that needs to be done. For example, an air gap which has become too large is detected in good time. Safety becomes visible, so to speak. Maintenance becomes plannable – the system operator or manufacturer is able to undertake maintenance in a targeted manner, aligned to their working processes. Furthermore, in case of problems, the error output also makes remote maintenance possible.

Ready for installation and easy to integrate

With its ROBA®-brake-checker, mayr® power transmission is the only company to have an intelligent solution for the sensorless monitoring of electromagnetic brakes in its standard portfolio. „Users are able to integrate the module easily and quickly into machines and systems without having to intervene in the ‚converter‘ or ‚control‘ components“, explains Andreas Merz, Product Manager at mayr® power transmission in Mauerstetten. „In this way they don’t take any risks as they don’t have to validate limit values and data themselves. We supply the ROBA®-brake-checker ready for installation and test all values beforehand. For users, this means a ‚plug-and-play solution‘, so to speak. In future, we will offer the module in a new, modern and functional design.“

Reliable lightweight brakes for robotics applications

mayr ® power transmission can look back on many years of cooperation with the Deutschen Zentrum für Luft- und Raumfahrt (German Aerospace Centre) for the development of lightweight construction brakes. „Our lightweight construction brakes, the development of which began almost 20 years ago during the course of the research project LBR II, have established themselves today as a marketable standard solution and prove themselves every day in numerous robotics applications worldwide“, explains Product Manager Bernd Kees. „Today’s challenge lies in effectively catering for diverse installation situations through an expedient modular construction.“

Sicherheit dSafety due to the fail-safe principleurch Fail-Safe-Prinzip

The brakes of the proven ROBA®-servostop® series are spring applied, electromagnetic safety brakes which work according to the fail-safe principle: When de-energized, helical springs press against the armature disk. The rotor with the friction linings, which is directly screwed together with the customer component, is held between the armature disk and the brake plate. When the power is switched on, a magnetic field is built up. The armature disk is attracted against the spring pressure to the coil carrier. The rotor is released and the motor can run freely. Fail-safe principle therefore means that, after switching off the power, or in case of power failure or EMERGENCY STOP, the brake works reliably and safely and keeps the axes in any position required. This serves the protection of people and materials and is, for example, just as important in medical technology as in industrial robots, which collaborate with people in production lines. If, for example, a power failure occurs during a working process, the robot arm undertaking the working step must be held immediately and accurately, and may not drop or crash in an uncontrolled manner.

Small brakes with high performance density

The safety brakes by mayr® power transmission guarantee reliable, constant holding torques over the entire service lifetime. They distinguish themselves through compact dimensions and are not only very lightweight, but also very fast when it comes to magnetic actuating. Furthermore, they feature high performance density, are wear-resistant and can be used even in demanding ambient conditions, for example at temperatures within the motor of up to 120°C. The brakes are also characterized by the high permitted friction work with dynamic braking actions: For servo drives, normally load mass ratios (load/motor) of 3:1 or smaller are selected for the benefit of good control characteristics and high dynamics. On the ROBA®-servostop® brakes, high permitted friction work and friction powers mean that load mass ratios of 30:1 and more are possible.

The simple and robust construction of these safety brakes allows simple, quick and reliable installation: The operating air gap is factory-specified. In contrast to permanent magnet brakes, exact axial positioning on the motor shaft is not necessary. The ROBA®-servostop® brakes always work accurately and reliably; the magnetic air gap is not influenced by the mechanical installation situation. „Every single safety brake, which leaves the plant, is subjected to a 100% inspection after final assembly and adjustment”, Bernd Kees summarizes. „All measured values determined are archived together with the respective brake serial number in our electronic database. This ensures 100% traceability – as reliability and safety do not allow for compromises”