Smart machine elements which provide important measurement data ensure transparency in the drive line. At the same time, they support efficient and predictive machine maintenance.

Smart machine elements which provide important measurement data ensure transparency in the drive line. At the same time, they support efficient and predictive machine maintenance. In addition to intelligent solutions for brake monitoring, mayr® power transmission has also developed new approaches for networked clutches.

Permanent inspection, demand-related maintenance, plannable and suited to the actual utilization, automated remote maintenance or cross-machine / cross-plant error analyses – these are the key aspects of tomorrow’s machine maintenance. mayr® power transmission offers solution concepts for the predictive maintenance of electromagnetic safety brakes based on permanent inspection, as these brakes are predestined components for the maintenance, safety and system availability, and permit conclusions to be drawn regarding the system operation. Monitoring of the safety brakes takes place without the use of sensors with the retrofittable ROBA®-brake-checker module.

Safety becomes visible

Through the extended analysis of current and voltage, the module detects the movement of the armature disk and knows what condition the brake is in. In addition to the switching condition, temperature and wear, the ROBA®-brake-checker also monitors the pull-in distance or tensile force reserve, i.e. whether the magnet is still able to release the brake. With the module, substantially more parameter are thus depicted during monitoring than with a conventional switching condition control. In the advanced version, the module is equipped with an additional circuit board with a customer-specific interface (e.g. optical, WiFi, IO Link, OPC UA etc.). Via this interface, data regarding the switching time, current, voltage, resistance, performance und relative attraction current can be generated. This means that processes can now also be evaluated, anomalies in processing procedures can be detected quickly and conclusions can be drawn from complex interrelationships. Safety and reliability become visible, so to speak. Maintenance becomes plannable and cost effective due to permanent inspection. The system operator or manufacturer is able to undertake maintenance in a targeted manner, aligned to their working processes. Furthermore, integration into remote maintenance systems is also possible.

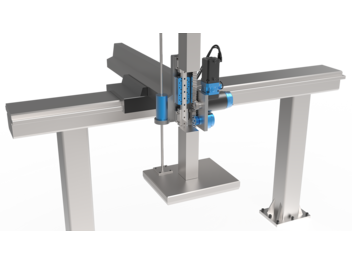

Smart, networked clutches

Smart couplings, however, allow for a look into the machine via the drive line as well. For more than 15 years now, mayr® power transmission has been dealing with the subject of process monitoring in the area of clutches, working with different systems here. Among other things, the company has continuously further developed the torque-measuring shaft coupling ROBA®-DSM, which provides very precise measurement data. „We will continue our approach not to focus on one specific measurement system or sensor type“, explains Ralf Epple, Product Manager at mayr® power transmission. „Our applications are just too diverse. And not every application requires the same data and the same sensor technology. And of course the costs should also always be kept in mind here, as in the area of process monitoring or analysis, the additional cost is often a decision criterion whether certain processes are monitored or not. Therefore, we have developed new, very cost-effective approaches for networked clutches. Everybody is invited to join us in breaking new ground.“