ES

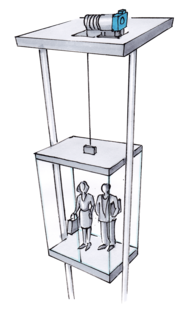

ROBA®-twinstop®: El freno de ascensor perfecto para accionamientos compactos

- Redundancia mediante varios circuitos de

- Montaje sencillo

- Ruidos amortiguados

- Diseño muy reducido

- Económico

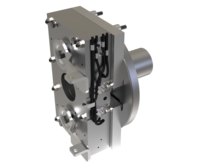

Dos circuitos de frenado independientes en un bloque de freno compacto

Los frenos

ROBA®-twinstop® son frenos electromagnéticos accionados por muelles en ausencia de corriente.

Cuando no reciben corriente, los muelles de compresión presionan contra las armaduras. De este modo, el rotor y sus forros de fricción se mantienen entre las armaduras y la superficie de atornillado de la máquina. El eje motor se frena mediante el rotor.

Si se aplica la fuerza magnética de las bobinas del portabobinas, las armaduras se atraen hacia el portabobinas venciendo la presión de los muelles. El freno queda libre y el eje puede rotar libremente.

Características

- Aplicación

- Para motores y accionamientos de ascensores y tecnología de escenarios

- Posición de montaje

- Montaje en el extremo libre del eje

- Seguridad

- Seguro gracias al principio de seguridad "fail-safe"

- Control del estado de conexión

- Apto para frenadas de parada de emergencia

- Redundancia gracias a dos circuitos de frenado independientes (EN 81)

- Certificado como dispositivo de frenado contra la sobrevelocidad en movimiento ascendente

- Ventajas

- Larga vida útil

- Versión

- Electromagnético

- Equipo

- Posibilidad de desbloqueo manual para cable Bowden o con palanca de desbloqueo manual

- Tipo de diseño y de protección

- Mecánico: tipo de protección IP10

- Eléctrico: tipo de protección IP54

- Montaje y mantenimiento

- Montaje sencillo

- Entrehierro preajustado

- Mantenimiento reducido

- Acústica

- Ruidos amortiguados

- Temperatura

- Clase de aislamiento F

- Ciclo de servicio

- Posible utilización hasta el 60 % del ciclo de servicio >60 % de aumento de la temperatura

- Calidad-precio

- Freno económico y redundante para ascensores

Certificaciones

We are happy to advise you

Do you have any questions about our products?

Your enquiry will be processed quickly and competently.

Your enquiry will be processed quickly and competently.

Chr. Mayr GmbH + Co. KG

Eichenstraße 1,

87665 Mauerstetten,

Alemania

Call us...

Tel.

+49 (0)8341 804-0

...or write to us

Correo electrónico

Escriba un mensaje