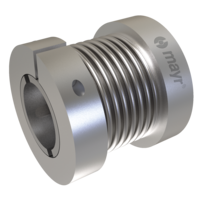

Acoplamientos de fuelle metálico: Acoplamientos para ejes rígidos a la torsión

El diseño patentado de los acoplamientos de fuelle metálico de mayr® garantiza la ausencia de mantenimiento y las dimensiones reducidas: así, los acoplamientos para ejes flexibles a la torsión evitan los errores de alineación tanto en sentido axial como radial o angular. Los acoplamientos alcanzan una larga vida útil con un montaje sencillo: nuestros componentes de acero y aleaciones de aluminio resistentes soportan temperaturas de hasta 250 grados, además de pares de giro y cargas de presión elevadas.

Nuestros acoplamientos de fuelle metálico se caracterizan por:

- Precisión de rotación sobresaliente

- Montaje sencillo de manera continua

- sin mantenimiento

Acoplamientos de fuelle metálico

- Apto para servoaccionamientos

- Compensación de desalineaciones entre lo

- Rígido a la torsión

- Sistema de montaje modular flexible

- Sin juego

Your enquiry will be processed quickly and competently.

A metal bellows coupling consists of a metal bellows with hubs on the input and output sides. The shape of the metal bellows allows torsion-free torque transmission while compensating for radial or angular shaft misalignment due to the bending of the metal bellows. This allows precise and accurate power transmission between the two shafts while ensuring torsional rigidity and robustness.

Our product smartflex® is configurable. However, please feel free to ask us directly and we will work with you to create your desired product exactly to your specifications.