Parques eólicos

We make the production of clean energy safe and efficient

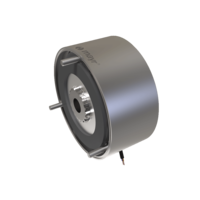

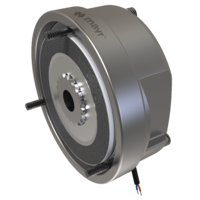

mayr ® power transmission bundles its know-how and decades of experience in the offshore sector in safety brakes for pitch and azimuth drives. The safety brakes for wind power plants represent maximum fail-safe function, minimum downtimes and constructional design diversity, and reduce the operating costs. The company sets new standards with its Cold Climate Version, which is certified for applications to -40°C by Germanic Lloyd (GL).

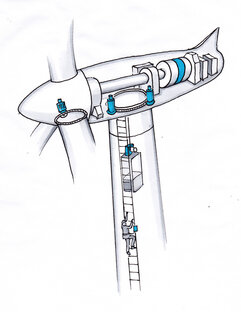

And the portfolio is also wide for torque limiters. It extends from overload systems for wind turbine gearboxes via torque limiters for climbing aid drives in the tower and switchable clutches for the drives of maintenance and installation platforms, right up to high-performance large clutches for gearbox test stands.

Check this before you select a Wind Power Brake:

Safe and reliable brakes control the trouble-free operation of wind turbines, whereas unreliable brakes in pitch and yaw systems can cause serious safety hazards. Not all brakes on the market are safe and reliable to use in those applications. You cannot delegate responsibility, so get involved and check carefully before you purchase a brake for the pitch and yaw system of a wind turbine.

- Which market position does the brake supplier have in the wind power industry and how many years experience does the supplier have?

- Take the time to visit the factory of the supplier. Seeing is believing. Does the supplier have state of the art quality processes, adequate qualification testing equipment?

- How is the brake torque specified? Is there test equipment available for static and dynamic brake torque?

- Does the supplier have climate chambers for brake testing at -40 °C up to + 60 °C and different levels of humidity?

- Does the brake supplier have a certificate, i.e. GL, confirming the compliance with the CCV low temperature requirements down to -40 °C?

- Can the supplier offer full traceability and provide serial numbers for each unit?

- Does the supplier have 100 % end line testing with automatic storage of all measured data?

- Is a high voltage test with min. 4000 V peek carried out for every brake to avoid unexpected coil damage in the field?

- In case of release monitoring: Is the switch already mounted, adjusted and tested by the brake manufacturer prior to delivery?

- Does the supplier have a world-wide network for support?

mayr® Wind Power Brakes Never compromise on safety!