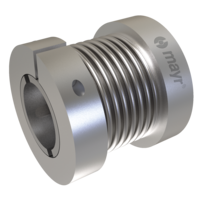

Metal bellows couplings: Torsionally stiff shaft couplings

The patented design of the mayr® metal bellows couplings guarantees freedom from maintenance and compactness: The torsionally flexible shaft couplings prevent misalignments in axial as well as in radial or angular misalignment directions. The couplings achieve long service lives with trouble-free assembly: Temperatures of up to 250° C, high torques or pressure loads are withstood without damage by the components made of steel and high-strength aluminium alloys.

This is what distinguishes our metal bellows couplings:

- Excellent concentricity.

- Positive locking, easy assembly

- Maintenance-free

Metal bellows couplings

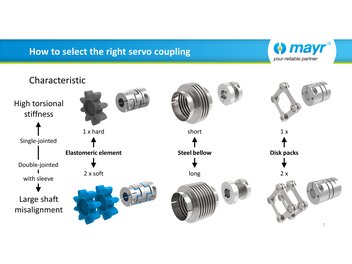

- Suitable for servo drives

- Compensation of shaft misalignment

- Torsionally rigid

- Flexible modular system

- Backlash-free

Your enquiry will be processed quickly and competently.

A metal bellows coupling consists of a metal bellows with hubs on the input and output sides. The shape of the metal bellows allows torsion-free torque transmission while compensating for radial or angular shaft misalignment due to the bending of the metal bellows. This allows precise and accurate power transmission between the two shafts while ensuring torsional rigidity and robustness.

Our product smartflex® is configurable. However, please feel free to ask us directly and we will work with you to create your desired product exactly to your specifications.