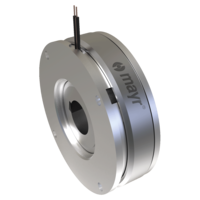

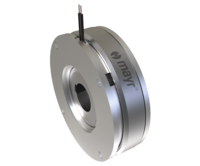

Electromagnetic clutches:

Electromagnetic, power-operated clutches from mayr® power transmission close when a DC voltage is applied and transmit torque frictionally. As soon as the current is cut, springs open the clutch. The electromagnetic clutches operate quietly and reliably up to their wear limit and short switching times and high switching frequencies allow high cycle frequencies in a wide range of applications.

The switching behaviour remains constant over the entire service life making the clutches extremely reliable and enabling precise positioning. As a result, electromagnetic clutches from mayr® power transmission ensure high operational safety for machines and systems. They are maintenance-free up to their wear limit which reduces both downtime and operating costs. The compact design of mayr® electromagnetic clutches offers a very high power density and allows them to be easily integrated into different applications.

Electromagnetic clutches

- Low noise level

- Long service lifetime

- High torque security

- Low friction work

- Can be used for 100 % duty cycle

Your enquiry will be processed quickly and competently.

The electromagnetic, power-operated clutches from mayr® power transmission close as soon as a DC voltage is applied and transmit torques frictionally. As soon as no more current flows, springs open the clutch. By applying a DC voltage to the magnetic coil, a magnetic field is formed. This pulls the armature disk to the rotor with friction lining. The torque is transmitted by frictional engagement.

The torque is transmitted from the drive element via the armature disk and the rotor to the output shaft. In the de-energised state, a diaphragm spring pulls the armature disk back to the drive element (e.g. belt pulley). This separates the torque transmission.

The ROBATIC® magnetic couplings from mayr® are not configurable. However, you are welcome to contact us directly with your product request - together we will find the right magnetic coupling for you.