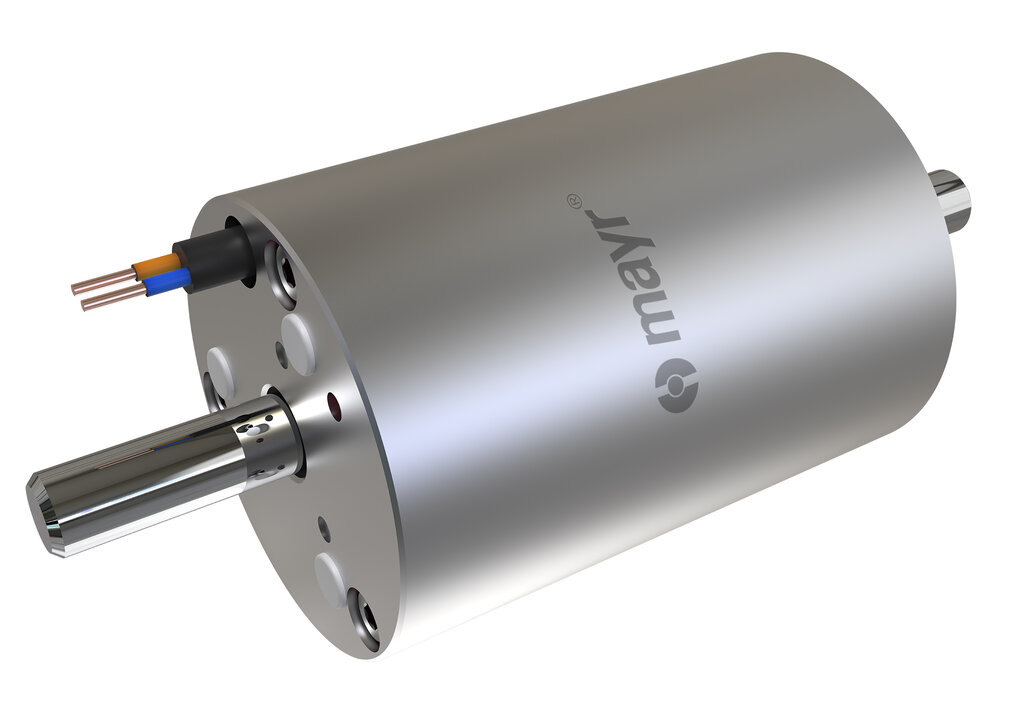

Electric motors in industrial applications are becoming increasingly popular. In more and more factory buildings, hydraulic or pneumatic systems have to make way and are replaced by electric drives. Here, an increasing number of reliable safety brakes are needed. With the new electromagnetic linear brake ROBA®-linearstop, mayr® power transmission now offers a fail-safe system with high holding forces, which can also brake dynamically and which convinces users with its short switching times.

Safety brakes, which have an effect on separate round rods or piston rods or on guide rails, are often used to safeguard linear movements. Depending on the application, pneumatically or hydraulically opening brakes, that reach high holding forces, are often used for this purpose. But drive axles are nowadays increasingly equipped with electic motors. Purely electrical systems – also for safeguarding – are the trend. "We are the only manufacturer to offer electrically opening linear brakes which are also safety brakes", explains Bernd Kees, Product Manager at mayr® power transmission in Mauerstetten. This means, the brakes operate according to the fail-safe principle. They generate the braking force through thrust springs and are closed in de-energised condition. The new series of electromagnetic ROBA®-linearstop brakes comprises six construction sizes with forces ranging from 70 to 17,000 N.

More than just clamping units

”Most linear brakes available on the market today serve as static clamping units, and have been designed to hold the axes safely at a standstill”, explains Bernd Kees. “However, there might be people under suspended loads during initial operation, maintenance or even during the production process without the load transfer to the mechanical linear brake having taken place first.” If the drive fails completely during these operating conditions, the linear brake alone is responsible for the reliable deceleration of the load. Which is why the safety brakes made by mayr® power transmission are also designed for such dynamic braking situations. The company has voluntarily subjected the brakes to a type examination as a safety component in accordance with the Machinery Directive (2006/42/EC).

Short switching times and reliable switching condition monitoring

In particular on vertical axes, short stopping distances are important for the safety of people and machines. The brake switching times are decisive for the braking distance, as during the free-fall time until the brake closes and the retardation takes effect, the mass additionally accelerates. The new electromagnetic linear brakes therefore impress with their short switching times. “In comparison to previously common products, our brakes switch faster by a factor of 10,” adds Bernd Kees. However, maximum safety is only achieved if the projected switching times are guaranteed over the entire service lifetime. This is why reliable switching condition monitoring is key. In the new electromagnetic ROBA®-linearstop brakes, the control module is used for this purpose. For larger brakes (from construction size 40), monitoring with proximity switch is also possible.

Outlook: New solutions for rails

In addition to linear brakes for piston rods, mayr® power transmission is currently also working on electric safety brakes for profiled rails. The new ROBA®-guidestop brakes for rails in the sizes 25 to 45 are almost market-ready.