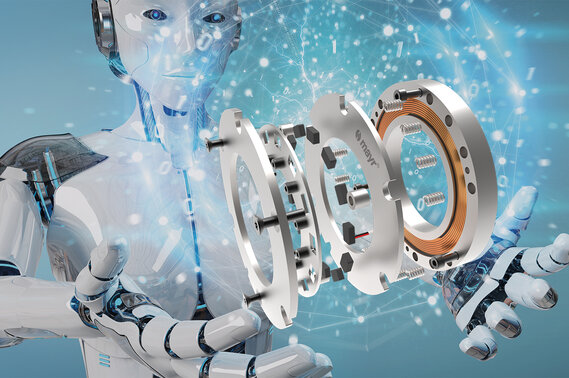

With its new standard modular system for robot brakes, mayr® power transmission not only offers more flexibility and guidance, but at the same time creates the basis for solutions at an attractive price. At sps 2023 in Nuremberg (Hall 4, Booth 278), the company also demonstrates how intelligent, communicating brakes and couplings can be cleverly used for process monitoring and thus get the drive line up to speed for Industry 4.0 while keeping costs low.

Safety does not allow for compromises – this is especially true for robots, which are often capable of complex and unexpected movements and, especially in the case of lightweight robots, sometimes even collaborate with humans with little or no distance between them. For this reason, robot arms must come to a standstill as quickly as possible in the event of an emergency or safety stop and must not descend in an uncontrolled manner after the power is switched off or in the event of a power failure. Slim, lightweight robot brakes manufactured by mayr® power transmission ensure the necessary safety. With the ROBA®-servostop® series, the company has developed safety brakes for servo motors which are specially tailored to the high demands of the robotics sector – not only in the industry, but also in the field of medical technology, for example. “The new standard modular system not only creates a high degree of flexibility for the various installation situations,” Bernd Kees, Product Manager at mayr® power transmission in Mauerstetten, explains. “It also provides users with easy and uncomplicated access to the brakes and a quick overview of the individual solutions, at an attractive price level.” And Mr. Kees adds: “We also provide access to the data necessary for dimensioning and selection, such as the definition of braking torques, switching times, mass inertia, friction work in the event of an emergency stop, the number of permitted emergency stops under various application conditions, or even information on the geometric connection. This in turn provides excellent guidance.”

Sensorless monitoring für integrated, small brakes

Reliable monitoring solutions are important for the safety of people and machines. Previously, it was not possible to monitor servo brakes due to the small air gaps or due to their installation situation. However, mayr® power transmission now offers an intelligent solution for sensorless brake monitoring. The retrofittable ROBA®-brake-checker module detects the movement of the armature disk through extended analysis of current and voltage, and knows what condition the brake is in. In addition to monitoring the switching condition and critical coil temperature, the module also performs preventative function monitoring for wear, functional reserve and malfunctions. In an extended version, the ROBA®-brake-checker module is equipped with an additional PCB with a customer-specific interface (e.g. Ethernet based). Via this interface, it can provide data on the switching time, current, voltage, resistance, performance und relative attraction current. This means that processes can now also be evaluated, anomalies in the process can be detected quickly and conclusions can be drawn from complex interrelationships; and also the integration into remote maintenance systems is possible.

Smart coupling for cost-effective process monitoring

And also the shaft couplings by mayr® power transmission can do a lot more than just transmit torques and compensate for shaft misalignments. They provide users with the opportunity to get to know their processes in detail in the first place. For example, the new torque-measuring shaft coupling ROBA®-drive-checker. Through permanent condition monitoring, it makes characteristic values and anomalies in the process visible quickly and reliably. Thanks to the M8 network connection, integration into remote maintenance systems is easily possible. These are important advantages – not only for the predictive maintenance, but also to lower maintenance costs and reduce technical defects and downtimes. The ROBA®-drive-checker has been designed for in industral applications. After all, it is not only insensitive to external interference, but also offers high functional reliability thanks to its robust design with IP6X certification.

Easy integration

The ROBA®-drive-checker is a new component in the proven modular system of the backlash-free disk pack coupling ROBA®-DS. The main elements are the multi-gateway and the ROBA®-drive-checker sleeve. As all connection options are available for the ROBA®-DS steel disk pack coupling, this cost-effective process monitoring system can be easily integrated into many existing applications. In addition, a connection to EAS® safety clutches is also possible.

Thanks to optical position markers and an intuitive configuration assistant, the multi-gateway is easy to position and configure. It supplies the rotating sleeve inductively with energy, manages the radio connection and provides the measurement and system data in the network. The permanent wireless energy supply means that there is no need for battery changes or charging. “The sleeve, installed between two ROBA®-DS disk packs, measures the torque with proven strain gauge technology”, Ralf Epple, Product Manager at mayr® power transmission explains and names additional advantanges: "The user retains complete sovereignty over the data transferred from the sleeve to the multi-gateway. External cloud systems or software from third parties are unnecessary. The ROBA®-drive-checker was developed 100% by mayr® power transmission. The company supplies the system as a complete package from a single source.”

mayr® power transmission at the sps in Nuremberg, Hall 4, Booth 278.