ROBA®-brake-checker: Intelligent brake monitoring

- Sensor-free brake monitoring

- Detects errors before they occur

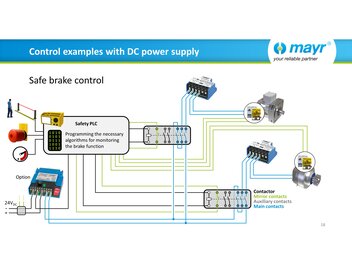

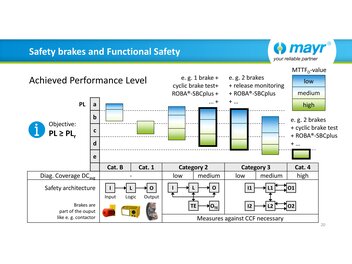

- Control and monitoring possible

- Can also be integrated into existing systems

- Suitable for many safety brakes

The ROBA®-brake-checker is a smart module for monitoring safety brakes. This means you can monitor the brakes’ status and function constantly. The ROBA®-brake-checker runs without sensor systems built into the brake, has no impact on the design, and is easy to retrofit. The switching device enables plannable maintenance, remote maintenance and maximum operational safety for your brake systems.

A permanent overview of the brake operating conditions

- Sensorless monitoring of switching condition, wear, critical coil temperature, and errors

- Maximum operational safety due to detection of errors before they occur

- Control and monitoring functions all in one possible

- Reliable and wear-free, independent of the cycle frequency and the number of cycles

- Can be used flexibly for wide ROBA-stop® brake spectrum

- Can also be integrated easily, quickly, and cost-effectively into existing systems

Safety becomes visible

- In addition to the signal itself, the module also supplies, for example through an optical interface, data on the switching time, the current, the voltage, the resistance, the performance, and the relative attraction current.

- Using an evaluation program, users can see whether everything fits or whether there is a need for action.

- Maintenance becomes plannable, and even remote maintenance is possible.

ROBA®-brake-checker: Intelligent switching device for brake monitoring

When it comes to safety brakes, compromises are out of the question. With ROBA®-brake-checker, you can equip your brake system with a switching device from the latest generation. The ROBA®-brake-checker constantly monitors your system’s safety brakes: the circuit module warns of any abnormalities before a fault even occurs. With this monitoring module, regular maintenance is a thing of the past.

ROBA®-brake-checker by mayr® power transmission

mayr® power transmission is a market-leading, globally certified company producing safety brakes, torque limiters, and shaft couplings. These design elements are key for the safety of passenger elevators, wind power plants, and in mining and tunnel construction. As a company with a long tradition, mayr® power transmission stands for reliable, highly technically complex development and production.

The ROBA®-brake-checker was developed as a switching device for the purposes of inspection, maintenance, and documentation of our range of ROBA-stop® safety brakes. The ROBA®-brake-checker fits seamlessly into existing systems and is delivered ready for installation. The control modules are also compatible with braking systems from other manufacturers.

Sensorless switching device ROBA®-brake-checker

The ROBA®-brake-checker supplies and monitors safety brakes without sensors. The ROBA®-brake-checker can therefore be retrofitted at any time and requires no specific device. The brake function and status are monitored by the ROBA®-brake-checker by analysing armature disk, voltage, and current. Wear, temperature, and switching condition are constantly examined in order to be able to precisely assess all brake functions. If the control unit detects an abnormality or defect, this is played out using the optical interface and an analysis program. The operator is shown precise information and instructions on the display, e.g. “Service within the next 4 weeks”. This allows wear and defects to be dealt with quickly and effectively . Remote maintenance is also an option in many circumstances with the ROBA®-brake-checker.

Download catalogueCertifications

Downloads

Your enquiry will be processed quickly and competently.