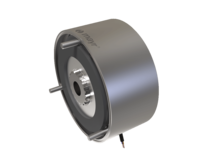

ROBA-stop®-M Servo-Pitch: For servomotors and regulated AC drives

- Designed especially for pitch drives

- Enclosed brake housing

- High performance density

- High permitted friction work

ROBA-stop®-M safety brakes are designed for installation at the free shaft end. They ensure reliable holding and can decelerate moving masses or loads in motion. In case of power failure, a fault, or malfunction of the servo brake in the drive motor, the ROBA-stop®-M brakes hold the axis in any position. This protects the drive and the system from damage.

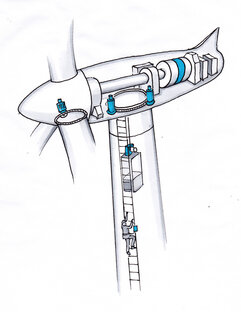

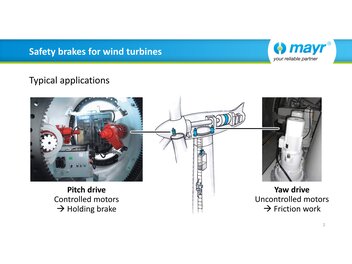

The application-optimized design of the ROBA-stop®-M safety brakes is suitable especially for pitch drives in wind turbines, which place very high demands on performance density and temperatures. Suitable for applications with ambient temperatures up to +90 °C and temperatures at the mounting flange up to max. +120 °C.

These brakes are perfectly designed for use in pitch servomotors as well as in controlled AC drives.

The ROBA-stop®-M brake is a spring-applied, electromagnetic safety brake.

In the de-energized state, helical springs press against the armature disk. The rotor is held between the armature disk and the relevant screw-on surface of the machine. The shaft is braked via the toothed hub.

When the power is switched on, a magnetic field is built up. The armature disk is attracted against the spring pressure to the coil carrier. The rotor is released, and the shaft is able to rotate freely.

The brake brakes reliably and safely in the event of a power switch-off, a power failure, or an EMERGENCY STOP.

Due to the enclosed construction of the application-optimized ROBA-stop®-M pitch brake, it can also easily be installed outside the motor housing, in contrast to servo brakes.

Product features

- Mounting position

- In the servomotor, A- and B-side

- Can be installed on the outside of the motor housing

- Application

- Variant developed specially for pitch drives

- Robust motor brake

- Duty cycle

- Can be used for 100 % duty cycle

- Safety

- Reliable due to fail-safe principle

- Suitable for EMERGENCY STOP braking

- Switching condition monitoring (optional)

- Benefits

- Short switching times

- High permitted friction work

- Design

- Electromagnetic

- Features

- Simple and robust design

- Assembly and maintenance

- Easy installation

- Low-maintenance

- Price - Performance

- Cost-effective motor brake

- Construction - Protection class

- Protection IP54

- Protection IP66 available

Your enquiry will be processed quickly and competently.